The Innovation of CrystDry™ Technology

Our proprietary CrystDry™ Technology offers a breakthrough in Omega oil processing by converting over 90% of Omega-rich oil into powder form. Using algae oil as an example, CrystDry™ can turn more than 90% of algae oil into powder, achieving an unprecedented 30% DHA content. In stark contrast to traditional microencapsulated powders, which have low conversion rates (10–20% DHA) and rely heavily on additives like maltodextrin, starch, carbohydrates, or proteins, CrystDry™ eliminates the need for these excipients—delivering a cleaner, more potent product.

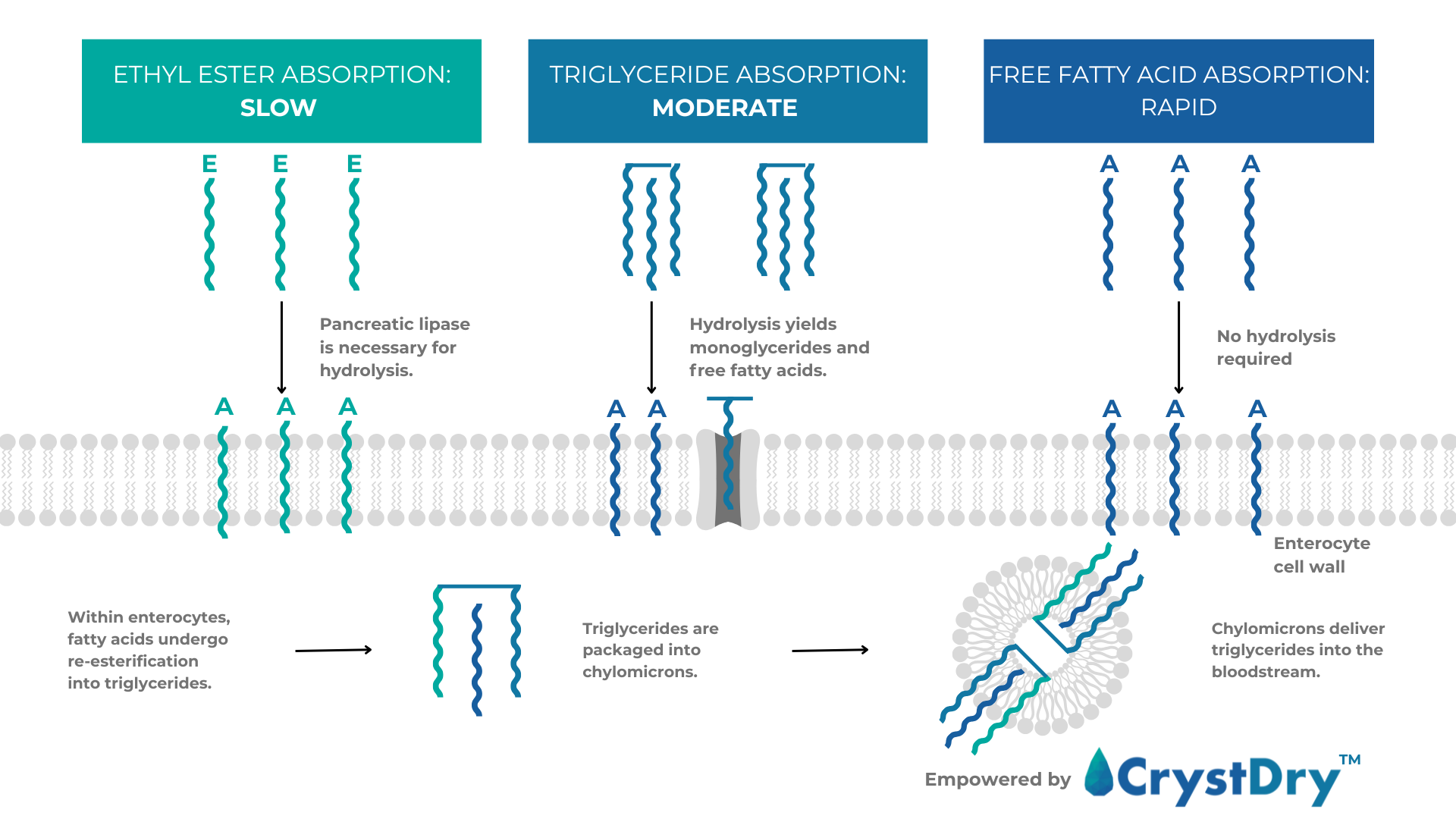

Moreover, CrystDry™ innovatively delivers DHA in a free fatty acid (FFA) form, which requires no enzymatic hydrolysis for absorption, ensuring 76% higher bioavailability. This optimized delivery system allows DHA to be absorbed directly through cell membranes, dramatically improving efficiency and effectiveness. By combining unparalleled DHA purity, superior absorption, and additive-free formulation, CrystDry™ offers manufacturers a competitive edge in creating next-generation Omega-rich products.

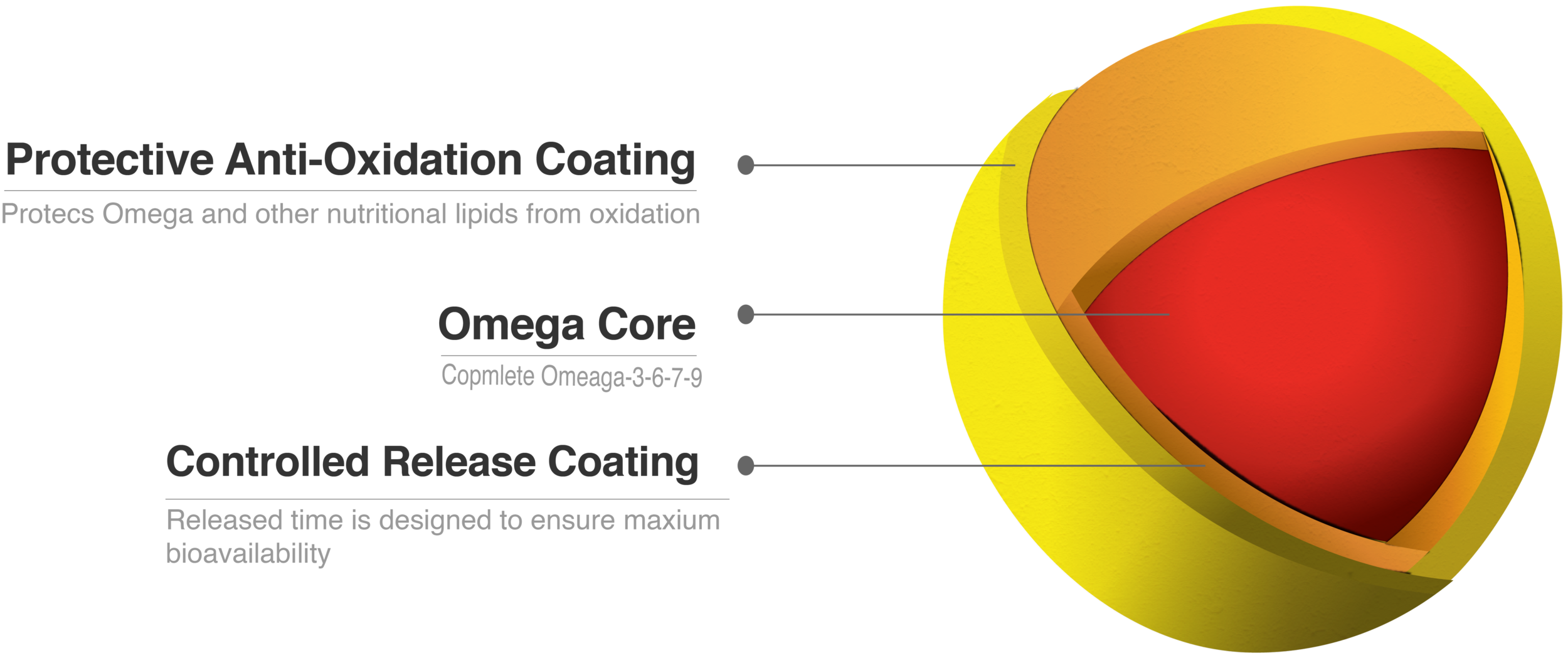

TRICAP™ Microencapsulation Technology

Graphical Demonstration of TRICAP™ Micro-encapsulation Technology

A majority of the bioactive nutrients in sea buckthorn comes in oil forms, including Omega-3-6-7-9, beta-carotene, and vitamin E. And their applications are limited to mainly softgel or ready-to-use oil.

With our advanced microencapsulation technology, Puredia incorporates the functional lipids from sea buckthorn with selected carbohydrates. This leads to the creation of a series of water-dispersible nutritional lipids powder, namely Omega Powder.

This technology provides formulators with more flexibility in formulation design and allows more convenient and innovative applications. The additional microencapsulation shell also protects the easily-oxidized nutritional lipids from oxidation and allows controlled release of the nutrients, ensuring the best bioavailability.

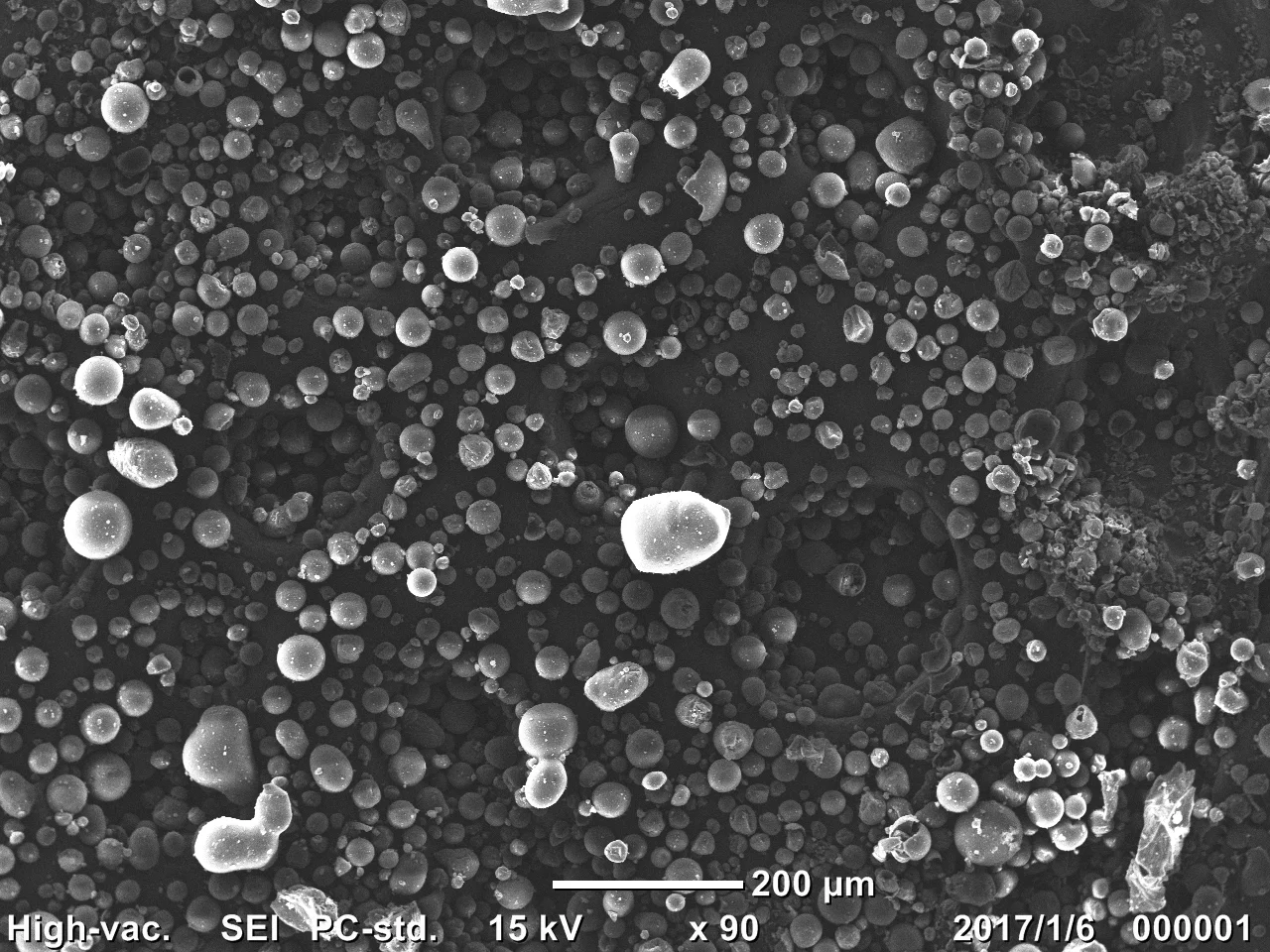

Below is a picture of the scanning electron microscopy (SEM) of Puredia SeaBerry® (Sea Buckthorn) Omega Powder, which shows the complete encapsulation of tiny lipid droplets into powder form.

SEM Image of Puredia SeaBerry® Omega Powder at 50μm

SEM Image of Puredia SeaBerry® Omega Powder at 200μm

Puredia Omegia® ingredients are made with Crystdry(TM) technology. The products include: Omegia® Powder, Omegia™ Oil and Puredia SeaBerry® OP2.0.

Puredia CardiOmegia™ ingredients are made with Crystdry(TM) technology. The products include: CardiOmegia™ Powder, CardiOmegia™ Oil and Puredia SeaBerry® OP2.0.